In today’s rapidly evolving industrial environment, manufacturing automation has become a pivotal factor for businesses aiming to boost efficiency, cut costs, and improve product quality.From robotic arms assembling car parts to software managing production lines, automation is transforming how factories operate. But what exactly is manufacturing automation, and how does it work?

This article delves into the different types of automation in manufacturing, its benefits, and how companies like EZSoft Inc. provide cutting-edge automation solutions for industries such as life sciences, food & beverage, and specialty chemicals.

Manufacturing Automation

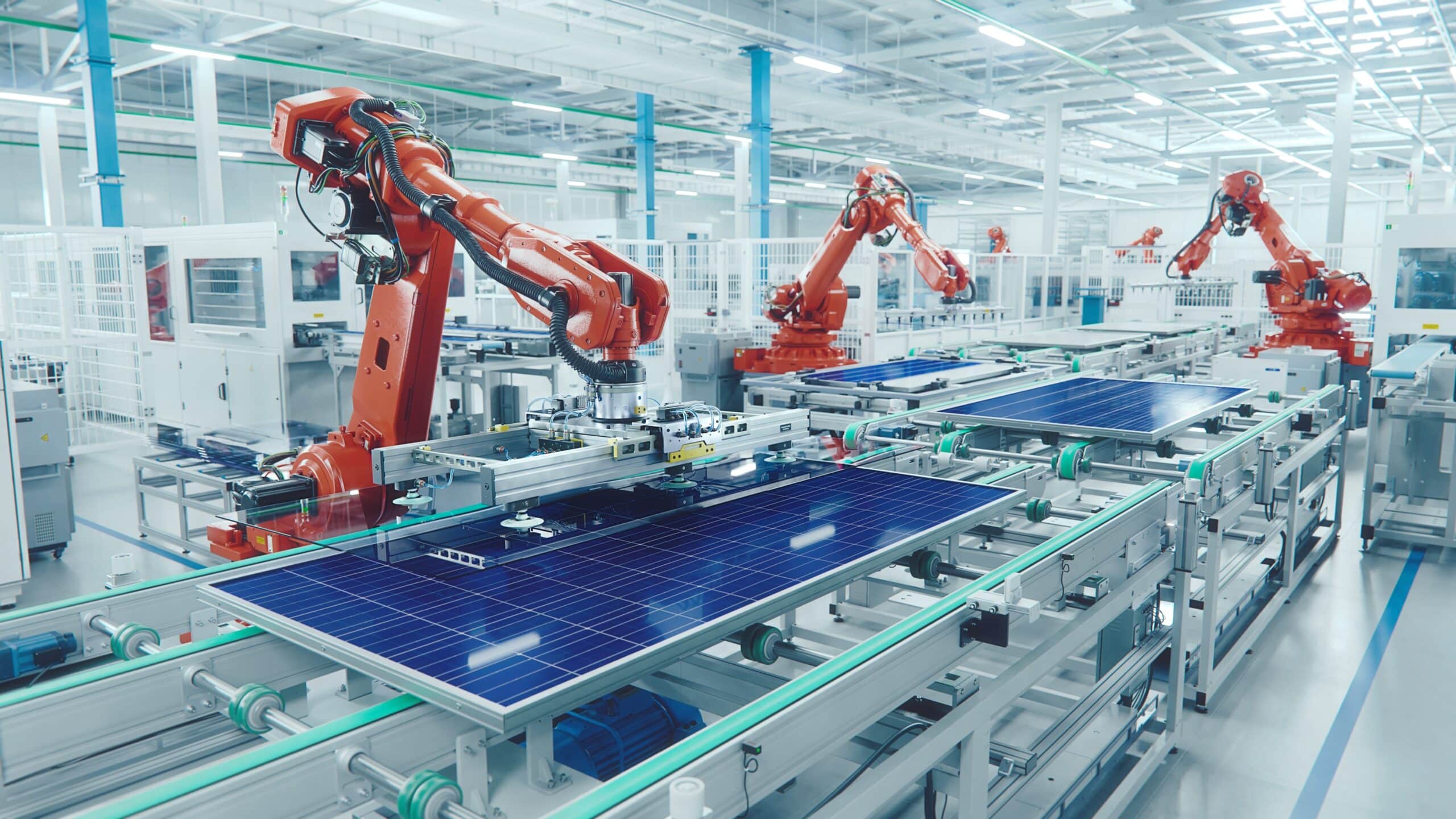

Manufacturing automation uses technology, robotics, and software to streamline production with minimal human intervention. By replacing manual labor with automated systems, it enhances efficiency, precision, and consistency in operations.

Automation reduces errors, speeds up production, and lowers costs, making it essential for modern industries. It includes robotic arms, AI-driven software, and advanced control systems that optimize manufacturing workflows.

Companies integrate automation to improve quality, safety, and scalability while meeting growing market demands. From automotive to pharmaceuticals, industries benefit from increased productivity and reduced downtime. This transformation is shaping the future of manufacturing, making processes smarter and more efficient.

Related Article: How Industrial Bakery Automation is Reshaping the Food Industry

The Role of Technology in Manufacturing Automation

Advancements in artificial intelligence (AI), machine learning, and the Internet of Things (IoT) have revolutionized manufacturing automation, making it more efficient than ever. Smart factories leverage real-time data analytics to predict equipment failures, optimize workflows, and minimize waste.

AI-driven systems enhance decision-making, while IoT-connected devices provide valuable insights for proactive maintenance and resource management. Automation not only improves productivity but also ensures higher precision and cost savings.

As industries embrace these technologies, manufacturers can achieve greater flexibility, scalability, and sustainability. This digital transformation is shaping the future of manufacturing, driving innovation, and enhancing overall operational efficiency.

Types of Manufacturing Automation:

There are four main types of automation manufacturing solutions used in factories today:

Fixed Automation (Hard Automation)

Fixed automation is built for large-scale production, using dedicated equipment programmed to carry out repetitive tasks with high efficiency. Common in car assembly lines, it ensures high-speed, high-volume manufacturing with minimal variation. While effective, it has limited flexibility, making it best suited for large-scale, consistent production with minimal changes in product design.

Programmable Automation

Used in batch process, programmable automation allows manufacturers to reconfigure machinery for different products. It suits industries requiring moderate flexibility, such as electronics or pharmaceutical manufacturing. Although setup adjustments require time, this system supports varied production without full automation, offering a balance between efficiency and flexibility for diverse manufacturing requirements.

Flexible Automation

Offering real-time adaptability, flexible automation enables quick product variations without reprogramming. Common in CNC machining and robotic systems, it responds to changing designs or demands with minimal downtime. This automation type enhances customization, making it ideal for industries requiring agility, such as aerospace, consumer electronics, and medical device manufacturing.

Integrated Automation

A fully automated system managing all production aspects, integrated automation combines robotics, AI, and IoT for seamless operations. It minimizes human intervention, optimizing efficiency, quality, and consistency. Found in advanced manufacturing facilities, it controls processes from material handling to final assembly, ensuring precision and continuous production with minimal disruptions.

Related Article: Making Sense of Industrial Automation Controller Options For Bakeries

How Does Manufacturing Automation Save a Manufacturer Money?

A major factor motivating a manufacturing company to adopt automation is cost reduction. Here’s how automation helps lower expenses in manufacturing:

Lower Labor Costs

Automation reduces reliance on manual labor by handling repetitive and time-consuming tasks. This decreases payroll expenses, minimizes human errors, and improves efficiency. Industries benefit from lower operational costs while reallocating human workers to more strategic roles, enhancing overall productivity and workforce optimization in manufacturing environments.

Increased Productivity

Automated machines operate continuously without breaks or fatigue, significantly boosting production output. Unlike human workers, they maintain consistent performance 24/7, meeting high-demand manufacturing needs. This leads to faster turnaround times, improved supply chain efficiency, and greater scalability, allowing businesses to meet customer demands with enhanced speed and reliability.

Reduced Material Waste

Precision automation minimizes human errors, reducing scrap materials and production defects. AI-powered systems and advanced sensors provide precise measurements, optimizing material usage. This cuts costs while promoting sustainability by reducing waste, making manufacturing more efficient and eco-friendly over time.

Energy Efficiency

Intelligent automation systems enhance energy efficiency by regulating power usage according to demand. AI-driven monitoring ensures machines operate at peak efficiency, reducing unnecessary energy waste. This lowers utility costs and enhances sustainability, making automated manufacturing an eco-friendly solution that benefits both businesses and the environment.

Does Marketing Automation Work for Manufacturing Automation?

Beyond the production floor, automation is revolutionizing marketing in the manufacturing industry. Digital transformation enables professionals to enhance customer engagement through automated Customer Relationship Management (CRM) and Enterprise Resource Planning (ERP) systems.

These tools streamline order tracking, predict demand trends, and improve overall efficiency. By leveraging AI-driven analytics, manufacturers gain valuable insights into customer behavior, enabling better business decisions and personalized marketing strategies.

Automation also optimizes inventory management, reduces lead times, and enhances communication between departments. As a result, manufacturers can improve productivity, reduce costs, and deliver superior customer experiences in an increasingly competitive market.

Related Article: How Can Automation Control Systems Integration Benefit Your Manufacturing Businesses?

Robots in Manufacturing Automation: The Future of Production

The rise of manufacturing robotics has transformed factory operations, enhancing efficiency and precision. Companies utilize robotic arms for assembly, autonomous vehicles for material transport, and AI-powered inspection systems for quality control.

These innovations reduce errors, increase production speed, and streamline workflows, making modern manufacturing more efficient and economical.

Benefits of Robots in Factories

Improved Accuracy

Automation eliminates human errors, ensuring precise and consistent product quality. Robots perform tasks with high accuracy, reducing defects and rework. Advanced sensors and AI-driven systems enhance precision in manufacturing, leading to better reliability, improved customer satisfaction, and higher efficiency in production processes across various industries.

Worker Safety

Automation enhances workplace safety by taking over hazardous tasks, reducing the risk of injuries. Robots take on risky tasks such as heavy lifting, exposure to hazardous substances, and high-temperature conditions. This reduces workplace accidents, creating a safer environment and enabling human workers to focus on less dangerous, higher-value responsibilities.

Speed and Efficiency

Automated robots operate much faster than human workers, boosting production speed and overall output. They operate 24/7 without fatigue, maintaining consistent performance. This leads to shorter lead times, improved supply chain efficiency, and the ability to meet growing market demands while maintaining high-quality manufacturing standards.

How Has Automation Changed Manufacturing?

The automation manufacturing industry has seen significant changes in the last decade. Here’s how automation is reshaping production lines:

Smart Manufacturing

AI and IoT enable predictive maintenance and self-optimizing production, helping to minimize downtime and enhance efficiency.Real-time data analytics help identify potential failures before they occur, ensuring seamless operations. This intelligent approach enhances productivity, minimizes costs, and enables manufacturers to adapt quickly to changing market demands.

Supply Chain Automation

Automated logistics and inventory tracking streamline supply chain operations, reducing delays and errors. AI-driven systems streamline inventory management, predict demand, and improve warehouse operations. This leads to improved efficiency, cost savings, and a more resilient supply chain that can quickly adapt to disruptions and fluctuating market conditions.

Customization at Scale

Advanced automation enables mass production of personalized products without sacrificing efficiency. AI-powered systems and adaptable manufacturing processes enable product customization tailored to individual customer preferences. This innovation meets the growing consumer demand for tailored solutions while maintaining cost-effectiveness and high-speed production capabilities in the consumer products industry and various other sectors.

Related Article: 6 Key Benefits You’ll Realize After Automating Your Bakery Processing Lines

A Manufacturing Company Plans to Begin Automating – Where to Start?

For businesses looking to implement automated manufacturing, partnering with an experienced systems integrator like EZSoft Inc. is essential. Companies should:

- Assess Current Processes – Identify inefficiencies and areas where automation can enhance productivity, reduce costs, and enhance quality, optimizing manufacturing operations for greater efficiency.

- Choose the Right Technology – Select automation tools that align with specific production needs, ensuring seamless integration and maximum efficiency in manufacturing processes.

- Train the Workforce – Equip employees with the skills to operate, manage, and maintain automated systems, ensuring smooth transitions and optimal performance.

- Monitor and Enhance – Perform routine assessments to boost automation efficiency, resolve potential challenges, and refine processes for ongoing productivity and cost reduction.

Industry-Specific Automation Solutions

Life Sciences

Automation ensures precision in pharmaceutical manufacturing, optimizing drug formulation and packaging. Computer Systems Validation guarantees regulatory compliance, maintaining strict industry standards. Advanced robotics and AI-based monitoring boost efficiency, minimize errors, and enhance product consistency, ensuring the production of safe, high-quality pharmaceuticals for patients while optimizing production processes.

Food & Beverage

Automated quality control systems uphold food safety standards by detecting contaminants and inconsistencies. Manufacturing Execution Systems (MES) integrate real-time data to enhance batch production, ensuring consistency and efficiency. Automation optimizes ingredient measurement, packaging, and logistics, reducing waste while meeting strict regulatory requirements and consumer demand for quality products.

Specialty Chemical

Automation improves safety in chemical processing by minimizing human exposure to hazardous materials. Advanced control systems enhance precision, reducing risks and ensuring consistent product quality. IT and Reporting Services simplify data management, enhancing compliance, efficiency, and traceability in chemical plants, while fostering sustainable and cost-effective manufacturing practices.

Related Article: How To Leverage Automation For Maximizing Output in Industrial Bakeries

Final Thoughts:

As technology evolves, manufacturing automation will drive the future of industrial production. Enhancing efficiency, reducing costs, and improving quality, automation is now a necessity, not a luxury. Companies adopting advanced robotics, AI, and IoT will stay competitive, ensuring faster production, fewer errors, and greater adaptability in a rapidly changing market.

If your business is considering automation in manufacturing,EZSoft Inc. provides expert systems integration, MES solutions, and IT services to help you transition smoothly. Contact us today to start your automation journey!

FAQs

What is automation in manufacturing?

Automation in manufacturing refers to using machines, software, and robotics to perform production tasks with minimal human involvement.

What are the four types of automation?

The four types are fixed automation, programmable automation, flexible automation, and integrated automation.

What kind of automation would you recommend for the manufacturing industry?

The best automation type depends on production needs. Fixed automation suits mass production, while flexible automation allows for product customization.

What does a manufacturing automation engineer do?

A manufacturing automation engineer designs, implements, and maintains automated systems to optimize factory operations.