Leverage automation for streamlined operations and higher accuracy.

Maximizing Output with Modern Automation

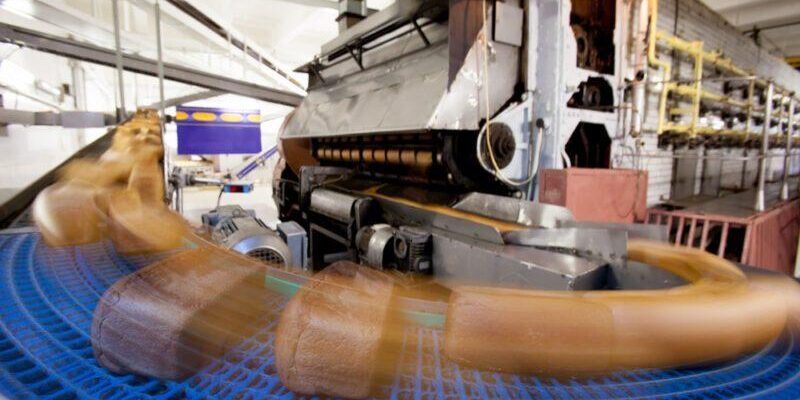

Modern automation software and production machinery have demonstrated an impressive capacity to maximize output in commercial bakeries of every size.

Reducing Manual Labor and Ensuring Consistency

The latest automated solutions for the food industry reduce dependence on manual labor and provide consistent production outcomes. The technology lets bakeries increase accuracy and process speed, ranging from dough mixing and shaping to packaging and labeling.

EZSoft: Optimizing Bakery Production

The latest automation solutions from EZSoft are no exception. Our software and information controls help bakeries optimize the production process while increasing the efficiency and speed of their production, thereby lowering their labor overhead and overall cost to operate. By automating your production now, your bakery can adjust to shifts in demand and increase its throughput in significantly in far less time than your current manual operations.

Adapting to Market Changes and Enhancing Food Safety

The flexibility and scalability of automation make it easier to pivot in response to unpredictable and rapidly shifting markets. Production efficiency aside, automation software and equipment can also reduce the risk of error and contamination by reducing human intervention.

Improving Accuracy and Reducing Waste

When you automate your processes, your bakery becomes more accurate, while the considerably lower chance of errors reduced the incidence of unplanned downtime and materials waste. Along these same lines, automating helps bakeries monitor production and track inventory, allowing them to maintain accurate records and keep track of production trends.

Automation for All: From Industrial to Independent Bakeries

For decades, automation software and equipment have been helping larger industrial-scale bakeries maximize their output by reducing manual labor, increasing accuracy, and providing detailed tracking and monitoring of their production processes. But how can the latest technology do the same for an independent bakery at an affordable cost? Let’s take a more in-depth look below.

Revolutionizing Fresh Bakery Operations

The latest onslaught of automation tools and technologies provides tremendous benefits for fresh and frozen bakeries alike. We’ll touch on what automation can do for frozen bakeries in the next section; but, in fresh bakeries, automating helps make production more efficient, allowing them to produce more of their products with fewer available resources.

Cutting Costs and Boosting Profits

Automated fresh bakeries are known for their low operating costs and their ability to increase profits by removing human operators from repetitive and mundane tasks like ingredient weighing, tracking inventory, and production scheduling.

Focusing on Growth and Innovation

Implementing industrial automation technology to their production lines allows bakers to allocate more resources to revenue-generating tasks and focus on more market analysis and product development. Inventory management and tracking also improve after automating, ensuring bakeries don’t run short on ingredients or supplies.

Enhancing Quality, Safety, and Efficiency

When you automate your fresh bakery, you’ll see immediate improvements in product quality and safety. Automation tools also help bakeries maintain product consistency and accuracy in their baked goods.

Ensuring Compliance and Freshness

Bakery production line automation enhances process monitoring, ensuring that your offerings are produced safely and in compliance with food safety regulations. Automation tools, likewise, reduce waste and improve product shelf life, ensuring that customers get the freshest products possible. Automation lets bakeries run more efficiently, reducing costs and improving profits.

Leverage Automation technology in frozen bakeries

As mentioned, Automation technology is a great asset for bakeries that deal primarily in frozen goods as well. Implementing automation tools and technologies can help optimize warehouse space and improve worksite safety.

Automating your lines will streamline the storage and retrieval of frozen bakery products, allowing for more efficient use of warehouse space. By utilizing automated storage and retrieval systems, bakery operations can reduce their storage footprint and optimize the use of their warehouse space.

AI technology improves workplace safety by reducing the need for manual handling of heavy materials and the potentially dangerous time spent inside freezers with subzero conditions.

Because automation tools reduce your reliance on human operators, the chance of errors and mishaps inside your freezer is considerably lower. Industrial automation technology ensures that frozen bakery products are handled properly and efficiently.

The potential benefits of implementing automation in frozen bakeries are significant. Automation can help optimize warehouse space, reduce manual handling of goods, and improve workplace safety. Industrial automation solutions for bakeries simplify the storing and retrieval process of frozen bakery products, ensuring that goods aren’t mishandled and costly injuries won’t occur inside your freezer.

When you implement modern automation tools and machinery, your frozen bakery can achieve more output through improved operational efficiency to foster a safer and more productive plant floor.

Bakery Automation and just-in-time order fulfillment

The bakery industry, and for that matter the entire food manufacturing sector is highly competitive. Businesses tend to operate on notoriously thin margins while putting in a tremendous amount of effort to ensure their products maintain the longest shelf life possible and aren’t discarded due to spoilage.

Automation software can help bakeries achieve this goal by providing them with the tools they need to efficiently manage their operations and maintain their products’ shelf life.

Industrial automation software lets bakeries optimize their delivery schedules for just-in-time delivery. This way, their products arrive at the destination as fresh as possible. By leveraging automation software, bakeries reduce the amount of time their products spend in transit so their products arrive at the point of sale as quickly as possible.

Bakery order management software allows bakeries to optimize their delivery schedules for just-in-time delivery. The software also lets them track their production processes and improve both the quality and consistency of their baked goods.

The latest automated process and order tracking software for bakeries identify areas of inefficiency in their production, allowing operators to make the necessary adjustments to ensure the same premium outcome every time.

Automation software lets bakeries monitor their products’ shelf life and make the necessary adjustments to ensure their products always remain fresh and safe to consume. By leveraging automation software, bakeries can preserve their short shelf life products, guaranteeing consistent, high-quality baked goods.

Where can I find leading industrial automation companies near me?

At EZSoft, we specialize in full-service integration of process control systems to bakeries like yours. Our automated recipe and batch management solutions offer easy product changeover, introduction and testing of new products, and consistent operation interfaces that minimize operator training and human error.

To learn more about how our industrial automation software can help increase productivity, reduce downtime, and eliminate errors, visit our website or give us a call now at (484) 568-5040.

Follow Us On Facebook